How to Extend the Lifespan of a Lowbed Semi Trailer

Regular maintenance and inspection are essential for maximizing the operational life of your lowbed semi trailer. Proper care ensures safety, cost efficiency, and consistent performance even under demanding transport conditions.

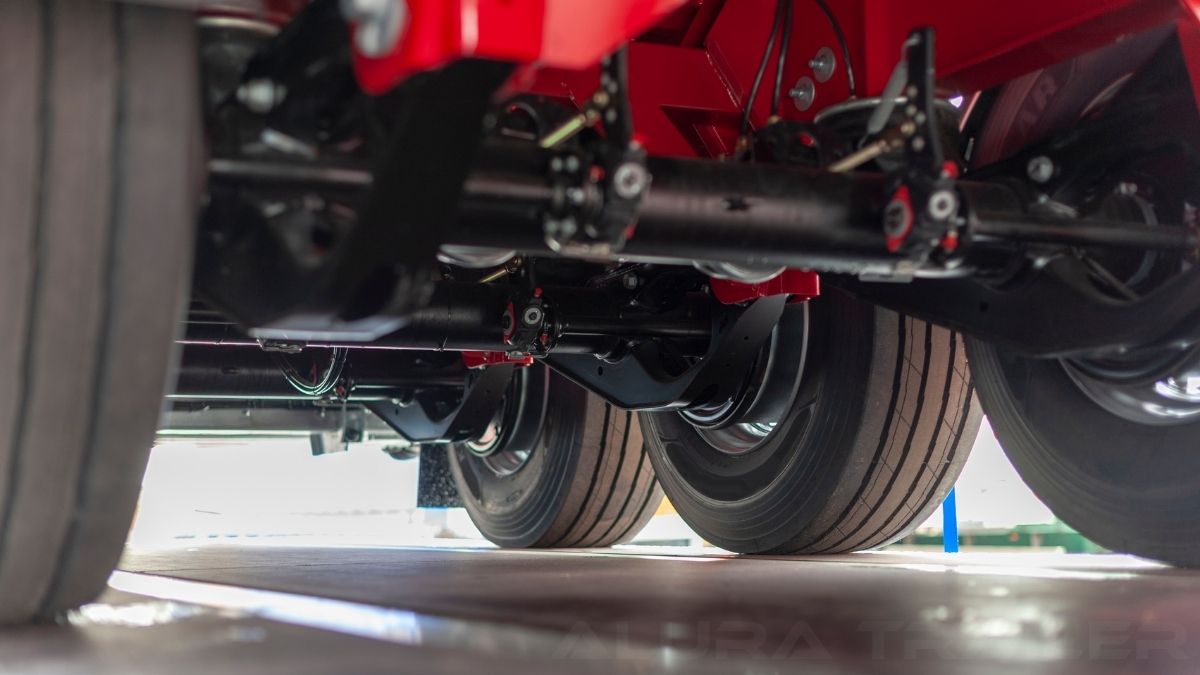

1️⃣ Routine Inspection Schedule

Inspect key components like suspension, tires, and braking systems at least once every 5,000 km. Check for cracks, corrosion, and wear on the main chassis beams. Regular lubrication of moving parts reduces friction and prolongs their life.

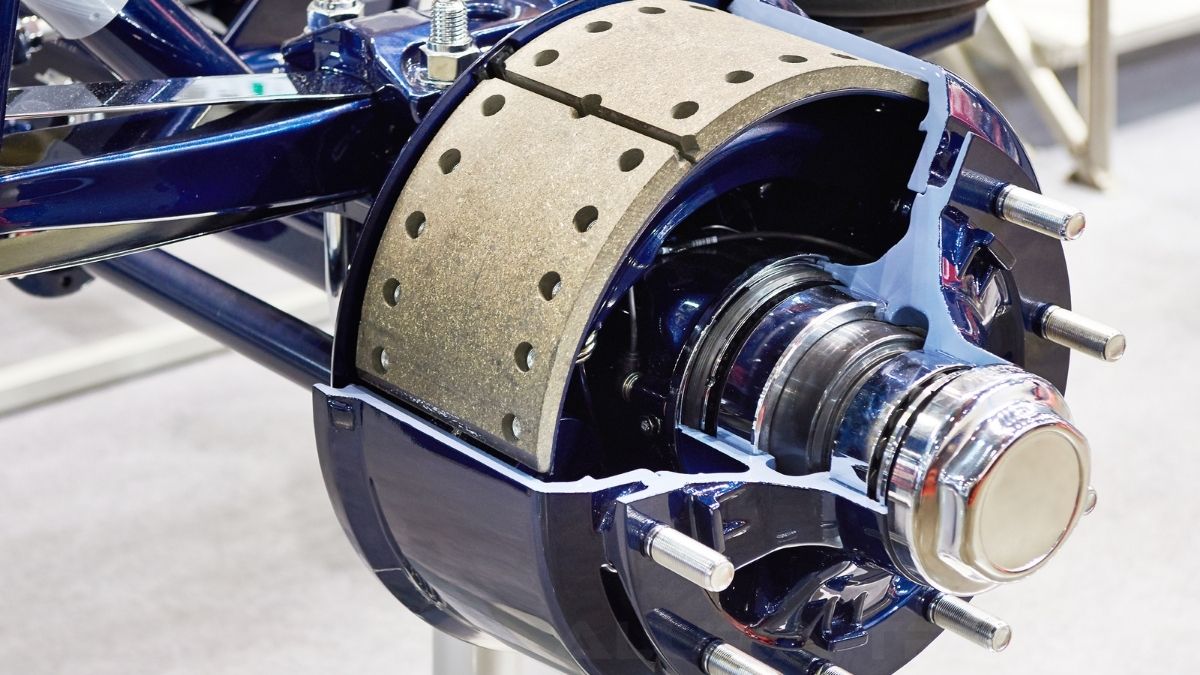

2️⃣ Tire & Brake System Maintenance

Lowbed trailers often carry heavy loads, which stresses tires and brake systems. Maintain correct tire pressure, replace worn-out brake pads, and ensure air lines remain clean and dry. This prevents heat build-up and improves braking response.

3️⃣ Protecting Against Rust & Corrosion

Regular washing and anti-corrosion coating are crucial, especially after long-distance or coastal transport. Alura Trailer’s hot-dip galvanized chassis provides extended resistance against humidity and road salt.

4️⃣ Proper Loading Practices

Uneven load distribution can deform the trailer’s frame. Use a weight balance chart and secure cargo properly using certified tie-down points. Avoid overloading beyond the declared payload capacity.

By following these best practices, you can easily add 5–10 years of reliable service life to your lowbed semi trailer.