Axle Maintenance Tips for Heavy-Duty Trailers

Axles are among the most critical components of any heavy-duty semi trailer. Regular inspection and proper maintenance not only prevent breakdowns but also ensure maximum load capacity and safety on the road.

1. Regular Inspection Schedule

Perform axle inspections at every service interval or after 10,000 km of operation. Check for oil leaks, worn seals, and corrosion on the spindle or hub area. Ensure all fasteners are torqued to manufacturer specifications.

2. Lubrication & Bearings

Proper lubrication prevents overheating and wear. Use high-temperature grease for wheel bearings, and inspect them for discoloration or pitting. Alura Trailer equips its trailers with maintenance-friendly axle hubs for faster servicing.

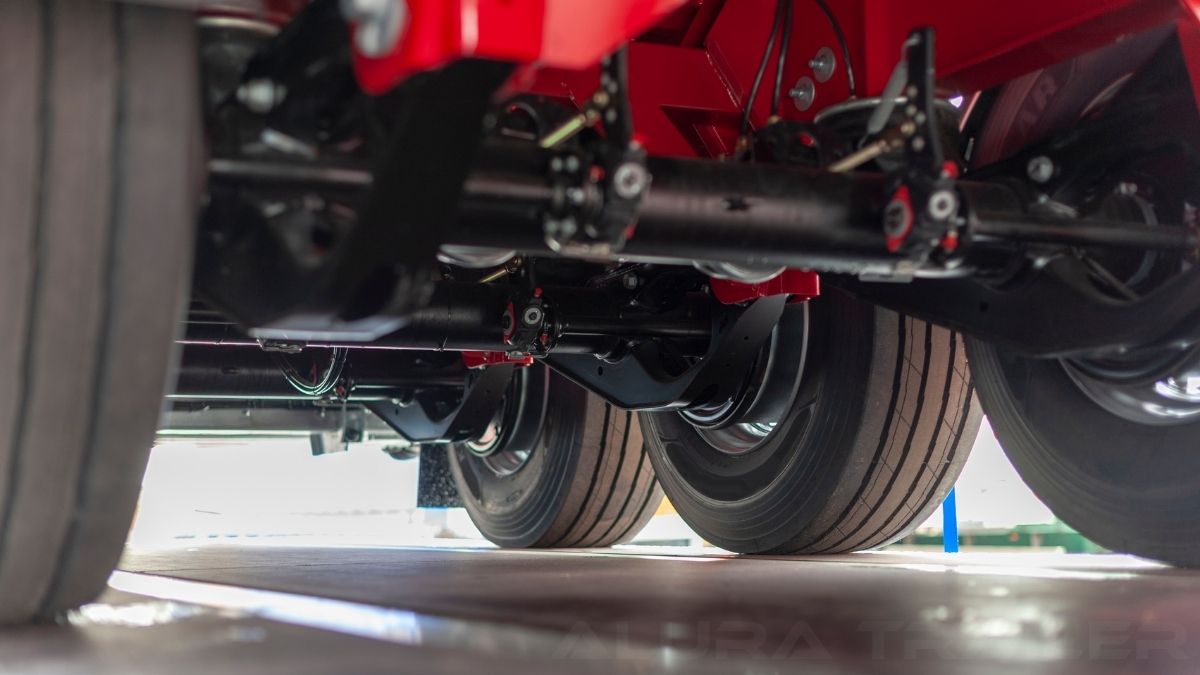

3. Alignment & Suspension Check

Incorrect alignment causes uneven tire wear and increased fuel consumption. Always align axles after replacing suspension components or after major impacts. Ensure that spring mounts and bushings are intact.

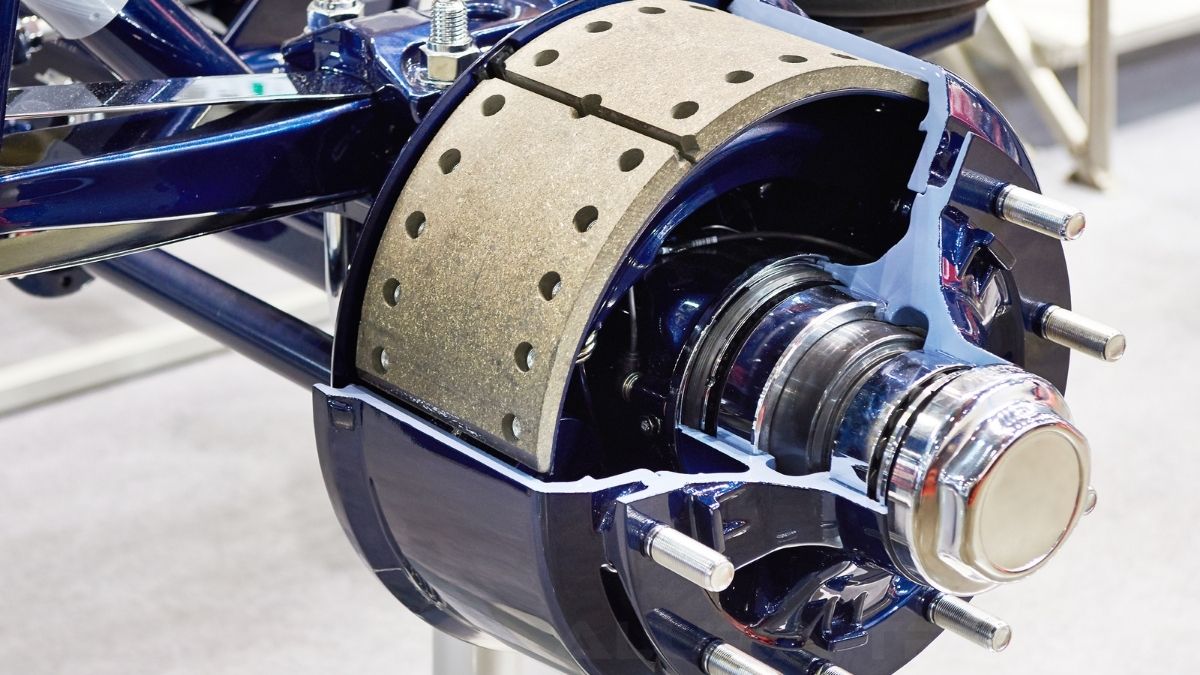

4. Brake Integration

Since brakes are directly connected to the axle assembly, maintain consistent inspection between the two. Clean air lines, check brake pads, and ensure that automatic slack adjusters function correctly.

5. Load Distribution Awareness

Overloaded or unbalanced axles cause premature bearing and tire wear. Follow the manufacturer’s payload distribution chart to maintain proper axle loading and ensure road safety compliance.

Regular axle maintenance is the key to longer lifespan, improved safety, and lower operating costs for every heavy-duty trailer.