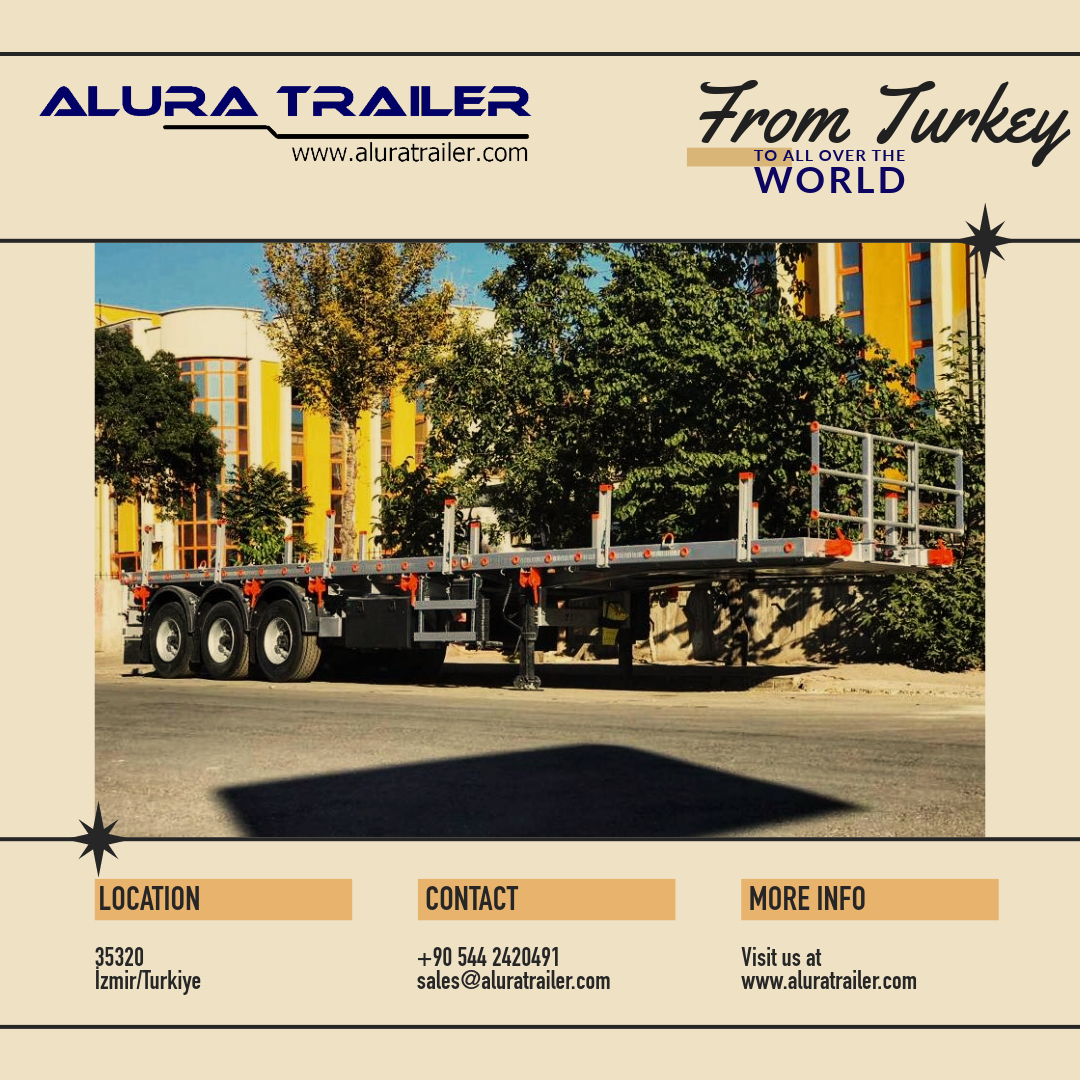

Flatbed Trailer Production in Turkey by Alura Trailer

Learn how Alura Trailer manufactures high-quality flatbed trailers in Turkey using certified materials, advanced welding technologies, and multiple suspension options for global transport operations.

High-Quality Flatbed Trailer Manufacturing

Alura Trailer is one of Turkey’s leading manufacturers of flatbed and extendable flatbed trailers for international markets. Each trailer is engineered using high-strength steel, advanced welding technologies and a strict ISO-controlled production process. Our flatbeds are widely used in construction, logistics, agricultural machinery transport, steel shipments, and containerized loads.

By combining lightweight frame technology with reinforced main beams, Alura flatbeds achieve optimal payload capacity without compromising structural durability.

Material Quality & International Certifications

All Alura Trailer flatbeds are manufactured using certified European steel and globally recognized quality standards:

- S355JR / ST52 High-Strength Steel for main beams

- ISO 9001:2015 quality management certification

- ISO 3834-2 certified welding processes for structural integrity

- EN 1090-2 EXC2 compliant manufacturing

- ECE R13 braking compliance for export standards

These certifications ensure that every flatbed trailer leaving the factory meets the requirements of European, African, Middle Eastern and CIS countries.

Suspension, Axle & Brake System Options

Alura flatbed trailers can be customized with multiple axle and suspension systems depending on the terrain, load distribution and customer preference:

- Air Suspension — ideal for long-distance highway transport

- Mechanical Suspension — preferred for rugged terrain and off-road usage

- BPW, SAF, ADR, Gigant Axles available on request

- Drum or Disc brake systems depending on transport regulations

- Dual-line EBS/ABS braking systems for maximum safety

Customers can choose between 2, 3 or 4 axle configurations, with optional extendable versions for 45–48 ft load requirements.

Advanced Production & Finishing

Flatbed trailers are produced using robotic welders, CNC plasma cutting, and fully shot-blasted surface preparation. The final coating includes:

- Anti-corrosion primer

- High-micron industrial topcoat

- Optional hot-dip galvanized chassis for extreme weather environments

This ensures long-term durability even in coastal, humid or desert climates.

Flatbed Trailer Technical Datasheet (Preview)

You can view the specification sheet below or download the full PDF file.

Need a High-Performance Flatbed Trailer?

Contact Alura Trailer to configure the right flatbed model for your transport demands — with custom axle, suspension and structural options.