How Many Axles Should You Choose for a 60 Ton Lowbed Semi Trailer?

Choosing the correct number of axles for a 60-ton lowbed semi trailer is essential for safety, efficiency, and regulatory compliance. The right configuration ensures even load distribution, better road handling, and longer component life.

⚙️ Why Axle Count Matters

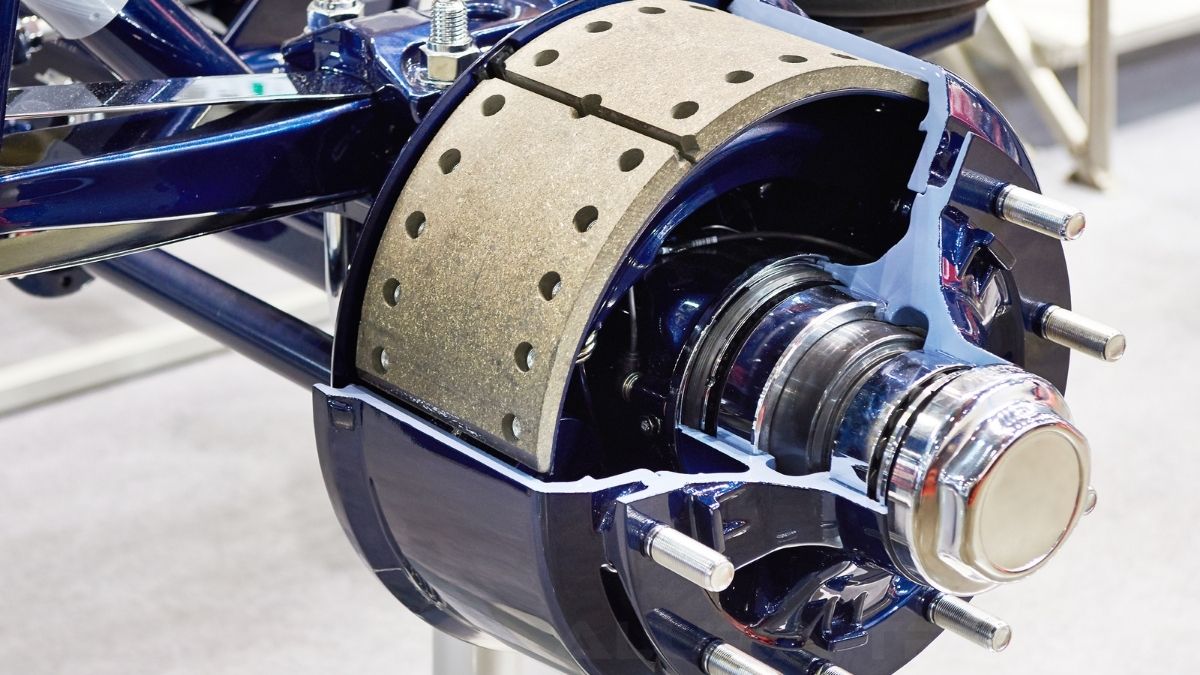

The total number of axles directly affects how weight is spread across the trailer. Each axle carries part of the payload, reducing stress on tires, suspension, and road surfaces. More axles mean lower load per wheel and improved road grip.

3-Axle Lowbed Trailers

Best suited for medium-duty transport up to 45 tons. These are lighter and easier to maneuver but may require special permits for heavier loads.

- ✔ Lower purchase cost

- ✔ Easier turning radius

- ⚠️ Limited payload for 60T cargo

4-Axle Lowbed Trailers

The most balanced choice for 50–60 ton loads. Offers great stability and performance for machinery, steel, or construction equipment transport.

- ✔ Ideal for 55–60 tons

- ✔ Compatible with ECE and EU weight limits

- ⚠️ Slightly higher maintenance cost

5-Axle Lowbed Trailers

For operators handling concentrated loads or long-distance heavy hauls. Enhanced weight distribution, braking, and suspension response ensure safety for payloads over 60 tons.

- ✔ Best for extreme loads above 60 tons

- ✔ Excellent road grip and balance

- ⚠️ Requires stronger king pin and gooseneck design

Axle Load Distribution Example

For a 60-ton load, a properly balanced 4-axle lowbed distributes approximately 15 tons per axle (excluding tractor load). EU regulations typically limit per-axle load between 10–12 tons, making a 4 or 5-axle setup ideal to stay compliant.

Alura Trailer Recommendation

Alura Trailer recommends a 4 or 5-axle configuration for 60-ton applications depending on suspension type, cargo length, and operating terrain. Each Alura lowbed trailer is engineered according to ECE R13 braking and EU weight standards, with options for mechanical or hydraulic suspension.